Damage resistance and roughness retention of work mills in cold rolling

Last Updated on Tuesday, 08 May 2012 14:30 Tuesday, 08 May 2012 14:26

Revue de métallurgie, Cahiers D’Informations, An International Journal for Steel and Other Metals: from Making to Using

Damage resistance and roughness retention of work mills in cold rolling

P.H. Bolt, D. Batazzi, N.P. Belfiore, C. Gaspard, L. Goiset, M. Laugier, O. Lemaire, D. Matthews, T. Nylén, K. Reuver, D. Stocchi, F. Stork, J. Tensen, M. Tornicelli, R. Valle, E. van den Elzen, C. Vergne, I.M. Williams

Vol. 107, Issue 6, pp. 245 – 255, 2010

ISSN (Print Edition): 0035-1563, ISSN (Electronic Edition): 1156-3141, EDP Sciences, Les Ulis, France,

ISSN: 0035-1563, DOI: 10.1051/metal/2010026,

presented also to the European Rolling Conference, 23-25 June, 2009, London

Abstract

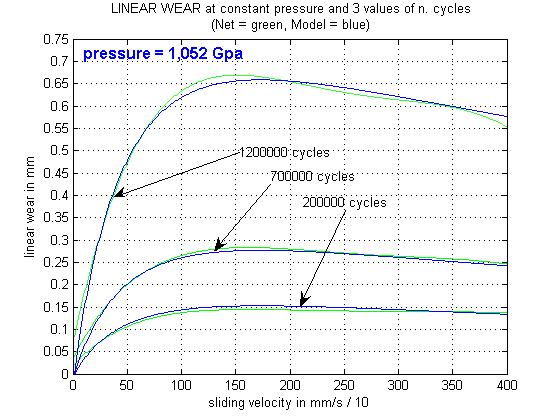

For every mill the ideal roll can be considered as one that can be used in a mill stand indefinitely. Unfortunately for the roll user, such ideal rolls do not exist. One major reason for work roll changes (planned or unplanned) is "wear". In the context of cold rolling and temper rolling, "wear" primarily refers to loss of roughness and/or surface texture. Another limitation to roll performance is the fact that mill incidents - minor as well as major incidents - inflict damage on the work rolls, requiring redressing in the roll shop. If a major defect is present in a forged roll, e. g. due to a mill incident, catastrophic roll failure may occur in a violent, explosive manner. Improvement of the value-in-use of a work roll implies a superior wear resistance, a superior damage resistance, and elimination of the safety risks associated with explosive roll failures. In order to deal with this in a concerted R&D approach, a consortium of two roll users in the steel industry, a leading roll manufacturer, a high-tech supplier of roll damage detection equipment, and specialised research institutes have joined forces. Cold rolling trials have been performed, using pilot mills as well as industrial mills, with both novel forged HSS work rolls and conventional forged 3-5% Cr steel work rolls. Separate trials have been designed to focus on either the aspect of roughness evolution or damage resistance. Complementary data from various laboratory tests and industrial mill and roll shop data have been collected. Models have been developed for damage evolution in a roll, and for roughness evolution of the roll surface. In addition, novel non-destructive detection systems and sensors have been designed and tested. This paper provides a concise overview of the results achieved.